Qimpro 25: Breakthrough at Tata Steel

Qimpro got its first breakthrough assignment from Tata Steel in 1988.

Russi Modi, in a private meeting with me at Bombay House, at first saw little merit in adopting quality improvement as an intervention at Tata Steel. His argument was that even the ‘seconds’ from Jamshedpur had a pent up demand. It was not until he grasped the Juran concept of Cost Of Poor Quality (COPQ), and it’s impact on the bottom line, that he challenged me to sell the concept to his top management.

A decade later, Dr J J Irani, Managing Director, Tata Steel, who led the quality revolution at Jamshedpur from the front, quoted “I personally spend considerable time in communicating with people, on how and why it is imperative for our company to change, to restructure itself, and to continuously and relentlessly reduce wasteful costs.”

In fact Tata Steel had become the hatchery for quality professional in the Tata Group.

Two decades later, Sunil Sinha, Chief Executive Officer, Tata Quality Management Services remarked “We at Tatas, are appreciative for our long association with Qimpro. Our valuable association dates back nearly two decades. Qimpro has helped the Tata Group immensely in quality improvement – especially in companies like Tata Steel – and has also helped to shape the minds of many of our Tata leaders, towards achieving excellence and breakthrough improvement.”

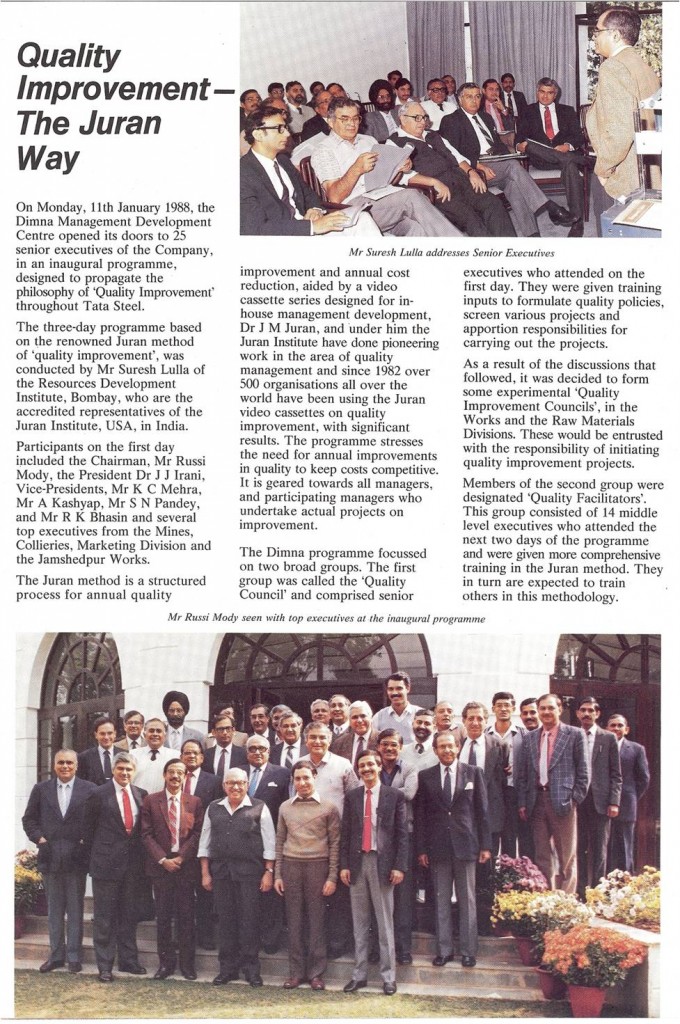

Below is a feature that appeared in an internal communication document of TATA Steel highlighting the initial three day workshop that happened on 11 January 1988.

Clarification: I started out as the Indian affiliate of the Juran Institute in 1986, through my proprietary firm, Resources Development Institute (mentioned in the article above). Once I got governmental approval for the name Qimpro, the name of my organization was changed to Qimpro Consultants Pvt Ltd.

I am part of ASQ’s Influential Voices and this post is in response to ASQ’s Blog: A View from the Q.