Dear PM, HM, FM……

Auto Industry

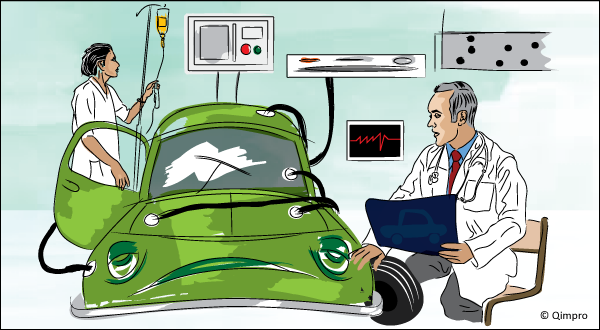

About three months back, the Indian auto industry had been admitted to (and still is in) the ICU of Hindustan Hospital. Apart from auto manufacturers, their suppliers and dealers are also in ICUs across the country.

It is worth noting that our auto industry is the backbone of the Indian economy. Further, each auto unit has adopted healthy Quality habits. This applies to earth moving equipment, tractors, commercial trucks, automobiles, and two-wheelers.

Currently, in this troubled economic scenario, most of the Quality Management talent in this industry is underutilized.

I see an opportunity. A win-win opportunity.

PSUs

Public Sector Units (PSU) across all industries, from commodities to power to airlines, have unhealthy bottom-lines. They are unwell and need transplants of heart, kidney, liver, and more.

The Cost Of Poor Quality (COPQ) at any PSU is likely to be 30-40 % of total costs. These wasteful costs are embedded in their serpentine managerial processes. In manufacturing / service-delivery, as well as support services and vendors.

PSUs must declare War On Waste, and reap the by-product harvest of reduced COPQ.

How? Appoint consultants. The underutilized Quality Managers from Maruti, Tata Motors, and Mahindra can serve as consultants, for a jump start.

And the consulting fee? Share the annual recurring COPQ savings for one year in the ratio 50:50!!!

COPQ

Let me demystify COPQ. There are three broad categories of wasteful costs (that is, COPQ) in any organization:

- Internal Failure Costs: These are costs associated with defects that are found before the product / service is delivered to the customer. Examples: Scrap; Rework; Downgrading; etc.

- External Failure Costs: These are costs associated with defects that are found after the product / service is delivered to the customer. Examples: Warranty charges; Complaint adjustment; Returned material; etc.

- Appraisal Costs: These are costs incurred in determining the degree of conformance to quality requirements. Examples: Incoming inspection and testing; In-process inspection and testing; Final inspection and testing; etc.

Organizations must incur Prevention Costs to keep Failure and Appraisal Costs to a minimum. Examples: Quality planning; Quality audits; Supplier quality evaluation; etc.

With the proposed 50:50 sharing of annual recurring COPQ savings for one year, I can see the auto industry coming out of the ICU. Further, PSUs will improve their business health.

Random Thoughts:

- We need to establish MADE IN INDIA as a Global Quality Benchmark, to attract global customers / collaborators.

- MAKE IN INDIA is only an invitation.

- Post World War II, a devastated Japan used Quality as a strategy to survive and succeed.

- CEOs in India must have a Quality Management orientation.

Excellent idea Sir!!! Hope it happens!!!

Absolutely the auto industry experts practice Lean day in and day out. They can also consult in state run hospitals to save lives.

I agree Sridhar.

Excellent Blog !

Alike good healthcare practices, auto industry must undergo preventive health check-ups i.e. annual performance excellence assessment.

A healthy system eats quality food and water and likewise healthy automobile companies needs to improve supply chain & supplier quality levels.

Thank you Sachin.

I like the manner in which you have demystified my message / appeal.

It is not only the need of the hour but a long term strategy – A community of people coming together to solve industry and social problems. Actually, the Government could use this community to solve many national problems. The biggest benefit will be our people involved and collaborating with the Government in nation building rather than being armchair critics! Wow, would love to see this happen! Hope Mr Lulla has laid the foundation for it!

Thank you Ashok for your appreciation.

Pray that this collaboration happens.