Partnering with the Phantom

Is quality popular? In theory perhaps. Not in practice.

Is quality a fully delegable responsibility? No.

This article appeared in Indian Management, November, 2017.

What are the challenges to muster support for a specific quality initiative? The key one is that upper managers believe that quality improvement projects offer lesser tangible rewards than other proposals.

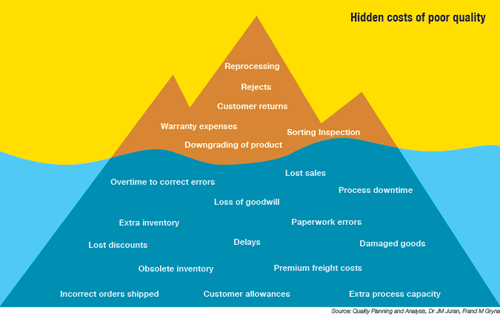

Dr J M Juran taught us to “scare up” support for quality initiatives. He advised: Speak the language of upper managers – MONEY. Although a quality improvement project may not directly influence revenues, it can dramatically reduce wasteful costs. These wasteful costs are the Costs Of Poor Quality (COPQ). These costs are traceable to a phantom factory within the factory dedicated to meticulously manufacturing waste.

An owner of a well reputed textile mill in Mumbai challenged my thesis: Over 25% of total costs are COPQ in a textile mill. I asked three leading questions:

- Do you receive customer complaints?

- Do you have incoming inventory?

- Do you have dormant inventory

The answer was “yes” to each of the three questions.

The owner and I invested time in stratifying customers complaints: Curry stains, rust marks, pigeon droppings, selvedge cut, short length, fading blue, etc. Each complaint was addressed complaint-by-complaint. Correcting some complaints cost more than others. The lost material, additional effort, and delivery delays were estimated in a COPQ table.

The owner also mentioned that some English customers had reduced their order sizes, preferring to purchase from Hong Kong.

On prioritizing the complaints based on frequency, enemy # 1 was pigeon droppings.

The Pareto based on COPQ identified a completely different enemy. Packaging. Goods that conformed (did not have more than 12 major defects; and more than 10 minor defects; per 400 meters) to specifications at dispatch, were unfit for use on arrival at customer site. Based on volume to be dispatched, the outsourced transport agency would use appropriate size trucks but of variable vintage.

The COPQ alarm was even greater at incoming inventory. Further, the ineffective sales forecasting system burdened the mill with dormant inventory.

Shocked with this validated information the owner wondered if he could double his profit without investing, partnering with the phantom! Could he think otherwise? As a consequence, the owner organized an executive briefing where he narrated his experience to the upper managers.

As per the phantom’s instruction, at subsequent monthly Quality Council meetings, the owner bolted the meeting room from inside at the dot of 8 am. Did he love this?!

Lessons Learned

- “Scare up” support for quality initiatives, using the language of upper managers, MONEY

- COPQ is managed by a phantom factory within the factory

- Dipstick for COPQ measurement: Customer complaints, and incoming inventory

- Upper managers must see the waste with their own eyes

- Perceived enemy # 1 is not necessarily the actual enemy # 1

- Processes that are not owned, such as logistics, can damage products that conformed to specifications

- Quality Council meetings should not be a COPQ