How to Assess Cost Of Poor Quality?

Language of Money

I believe: Halving your Cost Of Poor Quality (COPQ) can double your profit.

How often have you observed that we budget for inefficiencies? Once these inefficiencies are budgeted for, there is no alarm.

Chronic problems breed inefficiencies.

Example: We maintain incoming goods inventory to absorb the failure of goods delivered by our suppliers. Is this a COPQ? The problem is further magnified when banks extend loans against this inventory.

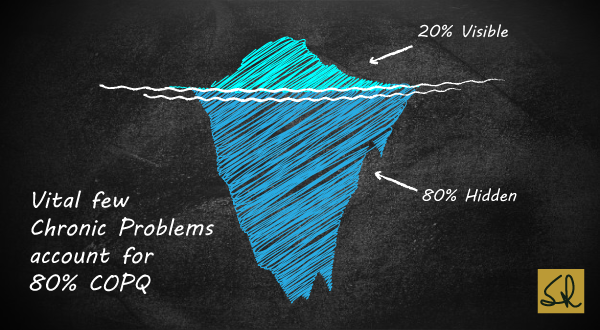

We have learned from Quality Capsule 3 that the vital few chronic problems account for 80% COPQ.

Here are a few insights:

- We start our Road to World-Class Quality by first establishing a formal quality management system.

- This quality management system is essentially a documentation of processes as they exist, or as we wish they should exist.

- The heart of any quality management system is a chapter on Continuous Quality Improvement (CQI).

- This chapter on CQI is, by and large, ignored.

- As a result, chronic problems get institutionalized. With that, COPQ too.

- All this eats into the bottom-line of an organization’s Profit & Loss Statement.

- As Qualitists, we must learn to speak to top management in their language – MONEY.

- Top management must prioritize chronic problems based on COPQ.

Categories of Quality Costs

COPQ can be decomposed into four categories:

- Internal Failure Costs: These are costs associated with defects (errors, non-conformance, etc) that are detected prior to the transfer of the product / service to the customer. These are costs that would disappear if no defects existed in the product / service before delivery to the customer. Examples: Scrap, rework, downgrading, etc.

- External Failure Costs: These are costs associated with defects that are found after the product / service is delivered to the customer. Examples: Warranty charges, complaint adjustment, returned material, returned patients, etc.

- Appraisal Costs: These are costs incurred in determining the degree of conformance to quality requirements. Examples: Incoming inspection and testing, in-process inspection and testing, final inspection and testing, evaluation of stock, etc.

- Prevention Costs: These are costs incurred in keeping failure and appraisal costs to a minimum. Examples: Process control, quality audits, supplier quality evaluation, training, etc.

How to assess COPQ ?

There are five steps for assessing the COPQ in an organization. The Quality Council must:

- Identify and map value creation processes (that deliver outputs to external customers).

- Identify and map support processes (that deliver outputs to internal customers).

- Identify and map supplier processes (that deliver inputs to the purchase department).

- Appoint a Senior Qualitist to walk the length of each process with a Cost Accountant and Human Resources Executive, to identify the chronic problems and estimate the related COPQ.

- Conduct a Pareto Analysis of the chronic problems, based on the related COPQ, process by process, so that top management can identify the vital few quality improvement projects to be solved by the vital few managers.

Now, refer to the question I had asked last week in Quality Capsule 3: Why should Quality, Finance, and Human Resource departments collaborate for quality improvement? My response is in four interrelated parts:

- Finance Department enjoys most credibility with top management.

- People make quality.

- Quality improvement is considered delegable by top management.

- Top management tend to see only the tip of the iceberg of COPQ.

My question to you this week is: What is the effect of COPQ on break-even point?

Next, my Quality Capsule 5 on Wednesday 5 August, will be on: Structured Quality Improvement.

The total Quality costs curve intersects the line of Declining trend of COPQ… indicates the Cost optimization or controlled Cost of Poor Quality

You are right Dr Krishnarao, We need Cost Optimization.

The cure should not cost more than the disease.

👍

I would add one more COPQ category. What is truly under the water for this iceberg & the biggest.

“Loss of customers.”

Getting them back takes a lot more than keeping. Often that loss is for their lifetime.

So big a cost, that most people would not know how to estimate or believe the good estimators.

Absolutely Vinay.

A Lost Customer is a Hidden COPQ. Besides, a Lost Customer is likely to speak to his/her friends and business associates about a bad experience with your offerings ( or how much better is an alternative).

Quite often, we don’t realize when we have lost a customer.